Custom Fabrication and Welding Services

Your Partner for Custom Fabrication and Welding

At Atlantic Millwrights Inc., we’re not just an industrial contractor, we’re a group of specialized fabricators and welders dedicated to assuring your customized metal structures and welded assemblies are expertly crafted, maintained, and even transported. Our talented team delivers unyielding precision and excellence from fabrication to assembly, disassembly, and even relocation, securing, and shipping of any substantial machinery or an entire production line.

Our fabricators and welders have been meticulously trained in the art of custom fabrication and welding. We’re committed to designing, constructing, aligning, maintaining, and troubleshooting customized metal structures and welded equipment to ensure seamless production.

When you select Atlantic Millwrights Inc. for your custom fabrication and welding services, you’re choosing a modest, family-run business that firmly believes in treating each project as a partnership and values client relationships above all else. A reputation like ours is not built overnight. We’ve been New England’s leader in fabrication and welding services since 1986. For over three decades, our fabricators and welders have time and time again demonstrated that there is no challenge too complex for us.

Custom Fabrication: An Overview

Custom fabrication is a game-changer in the world of manufacturing, enabling the creation of customized, high-quality products that cater to specific requirements. From expansive aluminum walkways for municipal water treatment facilities to large quantities of repetitive items like handrails and stairways for industrial facilities.

For over three decades, custom fabrication has revolutionized the way products are made, using welding equipment and other specialized tools to produce superior-quality workmanship. The craftsmanship and dedication in custom fabrication are what differentiate it from mass production, ensuring that every project is completed to the highest standards, with quality, fairness, and integrity as the utmost priority.

Custom Fabrication Techniques

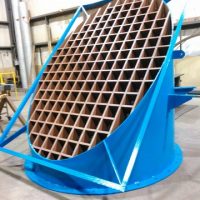

Custom fabrication is an art form, combining various techniques such as welding, metal cutting, and forming/machining to create masterpieces. Investing in experienced craftsmen and state-of-the-art welding equipment provides a competitive advantage, ensuring the best possible outcome for every project. One of the essential tools in this process is welding positioners, which assist welders in positioning weldments for optimal comfort and efficiency, reducing fatigue and expediting work.

Industrial welding automation is another aspect of custom fabrication, employing equipment with specific functions designed for a particular method or product. These advanced tools not only speed up the process, but also guarantee increased productivity, quality, profitability, and finish.

Welding

Welding is the backbone of custom fabrication, utilizing various methods such as MIG, TIG, and gas welding to join or separate metals. Arc welding is especially suitable for repair works and fabrication of structural steel. It can be used on a variety of heavy metals. Resistance welding is another efficient process, ideal for mass production of automobiles and making multiple spot welds in one go when joining large parts, due to its high speed.

Each welding technique has its own unique set of features, such as the inert gases and electrodes employed in TIG welding, which produces higher quality and stronger welds, as well as a superior finish with minimal post-weld cleaning. Custom fabrication projects typically utilize various types of welding equipment, such as oxy-acetylene welders, stick welders, TIG welders, and MIG welders, ensuring the perfect weld for every project.

Metal Cutting

In addition to welding, metal cutting plays a crucial role in custom fabrication, shaping and resizing raw materials to create the desired form. Techniques like sawing, shearing, chiseling, grinding, and milling are used to remove excess material from a workpiece, while plasma and laser cutting offer enhanced precision and accuracy, quicker cutting speeds, and improved safety.

Safety is of utmost importance in metal cutting, and it is crucial to wear proper protective gear, ensure proper ventilation, and follow all safety protocols when working with welding equipment and other potentially hazardous tools. With the right safety measures in place, custom fabrication professionals can create stunning products without compromising their well-being.

Forming and Machining

Forming and machining processes complement welding structural steel and metal cutting in custom fabrication, providing additional methods for shaping and refining products. Forming involves altering the shape of a partially completed product, such as sheet metal, through plastic deformation, while machining removes material from a workpiece using a cutting tool to create precise shapes and sizes.

These processes, along with welding and metal cutting, form the foundation of custom fabrication, allowing for the creation of intricate and specialized products tailored to specific customer requirements. With a diverse set of techniques at their disposal, custom fabrication professionals can craft virtually anything imaginable.

Atlantic Millwrights Carbon Steel Fabrication and Welding Services

- Rolling / Forming / bending and shearing facility

- VPP safety upgrade programs (hand rails, bollards, etc.)

- Catwalks, mezzanines, platforms and stairways

- Tanks / cones / chutes / duct sections

- Stainless steel / Inconel / AR plating / Hard Ox and overlay

- Precipitators, Bag houses, dust collectors & scrubbers

- Fabric filter hoppers fabrication & replacement

- Conveyor fabrication

- Drag, Quenching, screw, riddling, shaker pan, belt, bucket etc…

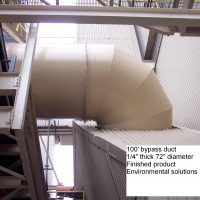

- Duct work, breaching, dampers, valves and repairs

- Diverter gates replacement, repairs and mechanical overhauls

- Turning vanes, vane packs and spray tower systems

- Feed chute replacement and relining with AR 400

- SDA Cone bottoms overlay and replacement with stainless steel

- SDA hoppers. Fabrication / removal and installation

- Leach ate water tanks. Fabrication and on sight installation

- By pass duct systems. Fabrication / installation and modifications

- Expansion joint & duct flanges replacement and repair

- Bag house. Fabrication / installation / relining and repair

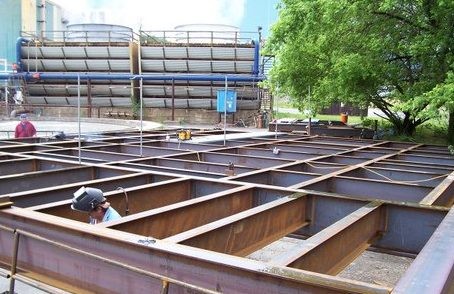

- Structural Steel / Certified Welding

- OSHA Safety Upgrades

- Conveyor Systems Repairs & Replacements

- Fabrication of tanks & Cones

- AR plating & Forming

- Machinery Bases & Modifications

- Mezzanine & walkways repairs, modifications, fabrication

- VPP Plant safety upgrades

- Rolling and Forming

- Chutes, Silos, Bins, Covers, & Doors repairs, modifications, fabrication

- Relining & Hard Facing Equipment

The Custom Fabrication Team

Behind every successful custom fabrication project is a team of dedicated professionals, including Solid Works designers, welders, machinists, and other highly-skilled craftsmen. These experts collaborate with clients to create products that are aesthetically pleasing, properly installed, and designed to provide long-term performance.

With decades of experience and a passion for their craft, the custom fabrication team at Atlantic Millwrights Inc. utilizes hand-selected materials and state-of-the-art welding equipment to bring each client’s vision to life. Their commitment to quality and attention to detail ensure that every project is completed to the highest standards, resulting in a final product that truly stands out for our clients.

Equipment and Tools for Custom Fabrication

A wide array of equipment and tools are employed in custom fabrication, ranging from hydraulic press brakes, shears, ironworkers, punches, hammers, engineer’s squares, calipers, rules, plasma cutters, and tube benders, to various types of welding equipment. These tools are essential for creating high-quality products that meet the unique demands of each project.

State-of-the-art equipment, such as 8-axis robotic welders and 5-axis waterjet cutters, provide an even greater level of precision and efficiency, ensuring that custom fabrication projects are completed with unparalleled quality. By investing in the latest technology and equipment, Atlantic Millwrights Inc. custom fabricators continue to push the boundaries of what is possible.

Ensuring Quality and Safety in Custom Fabrication and Welding

Quality control and industrial safety are paramount for custom fabrication projects. Quality control guarantees that the end product adheres to customer expectations and abides by industry regulations, while industrial safety guarantees that the fabrication process is conducted in a safe and secure environment. Implementing an in-house quality control program, adhering to industry standards, tracking and reporting inspection results, and dealing with nonconforming materials are essential quality control steps for custom fabrication.

A safe work environment is equally important, requiring protective gear, proper ventilation, and adherence to safety guidelines, especially when using welding equipment and other potentially hazardous tools. Health and safety remains a crucial and important pillar to Atlantic Millwrights Inc.

Quality Control

Quality control measures are critical in custom fabrication, ensuring that products comply with the necessary standards and are safe for use. Performing visual inspections of structural welds, for example, guarantees that the welds are of the utmost quality and will not cause any potential issues. Inadequate welds on an exhaust system can potentially cause hazardous substances to leak out, posing a risk to both the public and employees.

With a commitment to quality control and safety, Atlantic Millwright Inc. custom fabricators can deliver exceptional products that meet or exceed customer expectations.

Industrial Safety

Industrial safety encompasses the policies, measures, and techniques implemented to reduce the risk of injury, loss, and danger to persons, property, or the environment in any facility or workplace. Strict safety protocols and best practices protect workers and prevent accidents. These measures include wearing proper protective gear, ensuring proper ventilation, and following all safety protocols when working with welding equipment and other potentially hazardous tools.

Adhering to regulatory agencies is essential in order to guarantee that all safety procedures and optimal practices are being observed. Furthermore, compliance with regulatory agencies aids in safeguarding employees and avoiding accidents. By prioritizing industrial safety, Atlantic Millwrights Inc. custom fabricators create stunning products without compromising the well-being of their team.

Custom Fabrication Applications

The versatility of custom fabrication allows it to be beneficial in a variety of industries, including construction, automotive, aerospace, and manufacturing. Custom fabrication can be used for a wide range of applications, such as protective barriers, fences, screen doors, hoppers, and components for machines that require special specifications.

The benefits of custom fabrication include cost-effectiveness, enhanced quality, and expedited production times, providing increased flexibility and the capacity to craft specialized products not available in the market. With such a diverse range of applications, custom fabrication has the potential to revolutionize the way products are made, delivering exceptional results tailored to the unique needs of each client.

Choosing the Right Custom Fabrication Partner

Selecting a reliable and experienced custom fabrication partner is crucial to ensuring the success of your project. It is important to evaluate their expertise, technical proficiency, quality of output, communication proficiency, financial stability, and geographical proximity. Consider their experience in the specific type of project you are undertaking, as well as their technical capabilities needed to complete the project.

A good custom fabrication partner should produce high-quality work and have good communication skills to guarantee that the project is completed promptly and to your satisfaction. Additionally, their financial stability and proximity to the project site will help ensure a smooth and efficient process. By carefully considering these factors, you can select the ideal custom fabrication partner for your unique needs.

Your One-Stop Custom Fabrication and Welding Solution

Understanding your business needs and objectives is the core of Atlantic Millwrights Inc.’s service delivery. We are dedicated to partnering with you to provide custom fabrication and welding services tailored to your unique requirements, ensuring your industrial operations proceed smoothly and efficiently. Our expert fabricators and welders will provide you with detailed work procedures, blueprints, schematic drawings, layout plans, comprehensive instructions, and any additional documentation needed to ensure transparency in your project from inception to completion.

Atlantic Millwrights, Inc. is a family-run business, and our customer experience is central to our operations. It’s our mission not only to understand your needs and facilitate the smooth execution of your project, but our team also will build a lasting relationship built on trust with you during this process. Engaging with our customers in this way is our primary goal on every project. This close connection gives us a distinct edge and, truthfully, it is one of the most gratifying aspects of our work.

If you’re ready to partner with AMI on your next project, please contact us today.

Custom Fabrication and Welding FAQs

What is the meaning of custom fabrication?

Custom fabrication is the creation of custom-made materials through multi-stage assembly work for a particular purpose. It involves detailed planning and accurate fixturing.

What are the 4 main types of welding?

The four main types of welding are: Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), Shielded Metal Arc Welding (SMAW), and Flux Cored Arc Welding (FCAW).

Each welding process involves a different combination of equipment, technique, and materials to achieve the desired result.

What is the hardest welding to do?

Gas tungsten arc welding (GTAW) or TIG welding is the hardest form of welding to learn, due to its slow process and the need for a foot pedal to feed the electrode and control the variable amperage while maintaining a steady hand at the welding torch.

At the same time, it is also the most versatile form of welding, as it can be used on a variety of metals, including aluminum, stainless steel, structural steel, and titanium. It is also the most precise form of welding, as it allows for very precise control of the weld puddle.

What techniques are employed in custom fabrication?

Custom fabrication employs welding, metal cutting and forming/machining, utilizing specialized tools and welding equipment. These processes are used to create custom parts and components for a variety of industries, from automotive to aerospace. They are also used to repair and maintain existing structures and equipment. The skilled technicians at a facility are skilled technicians.

At Atlantic Millwrights we specialize in moving, installing, disassembling, and shipping heavy machinery. Our services include (but are not limited to):

- Complete mechanical support for outage or non outage projects

- Unlimited rigging capabilities

- Plant/Facility relocation and decomissioning

- Entire production line disassembly and installation

- Turnkey Millwright and rigging projects

- Conveyor installation, overhaul and modifications

- Refuse fuel feed conveyors overhaul and replacement

- Shaker / rubber belt and klinker conveyor overhaul and replacement

- Complete recycling systems glass / non ferrous / ferrous and separators modifications and installation

- Complete grate overhaul including carrying beams

- Rolling and reciprocating grate system rebuilds

- Complete feed table systems removal and installations

- Discharger overhaul / repairs and replacement

- Rooftop silencers / mufflers / HVAC and air makeup units

- Motor replacements to 2000 hp

- Pumping and hydraulic systems

- Air compressor and dryer systems

- Trommels / grinders / hammer mills

- Pumps / motors / centrifuges and rotating assemblies

- Precision and laser alignment

- Shafts / couplings / bearings

- Trucking and heavy hauling

- Machine shop services

- Motor & drive train foundation replacements

- Epoxy and high pressure grouting